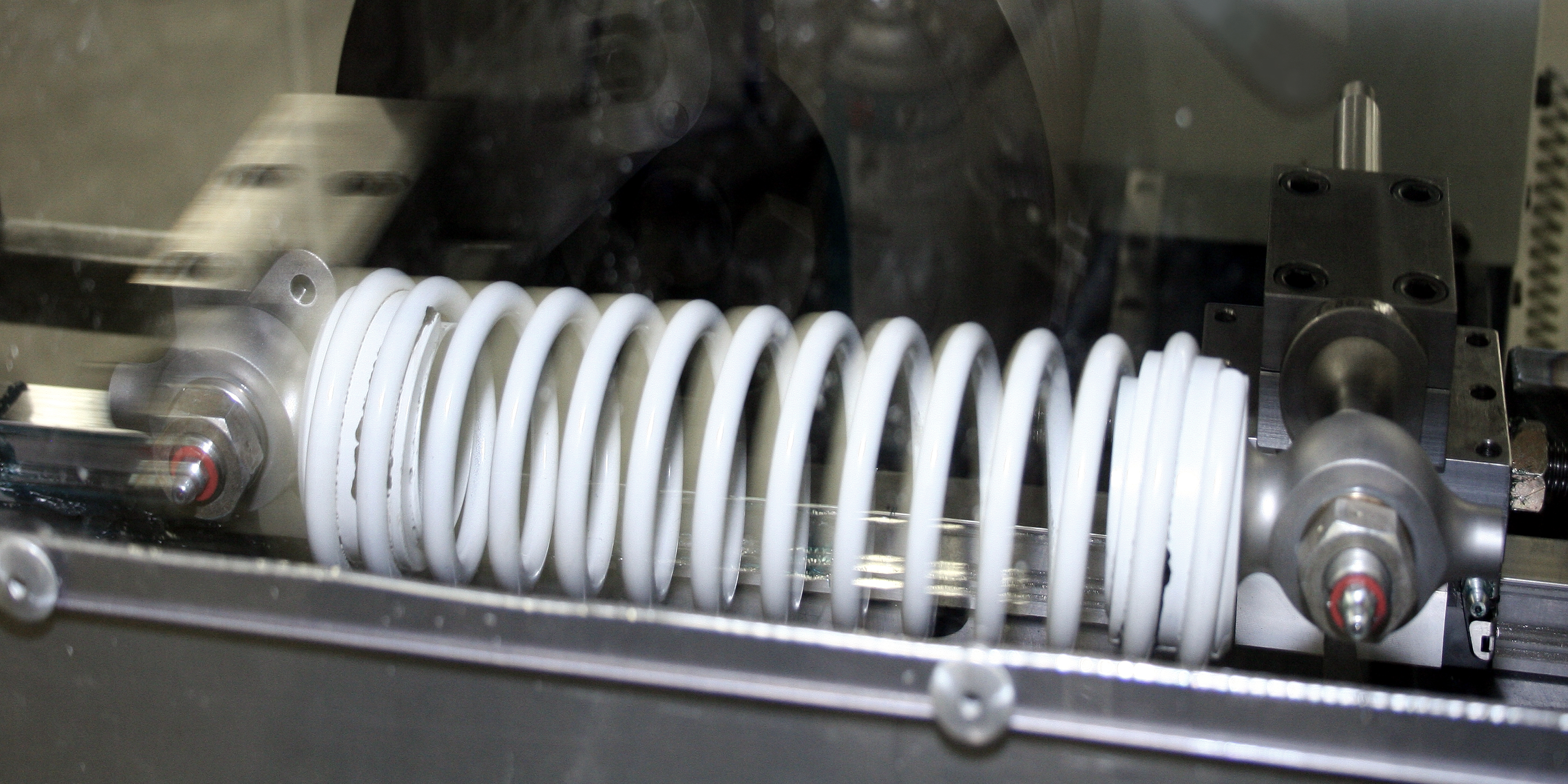

COMPRESSION SPRINGS

RCS can design and manufacture compression springs from 0.008" up to 1.375" diameter wire and bar stock. Round, square and rectangular cross sections are available for compression springs.

Renton Coil Spring Company is a world-class spring manufacturer for the aerospace, military, commercial, and motorsport markets, providing superior quality parts and performance since 1949.

Design and material capabilities, along with complete performance solutions has led RCS to become a top supplier of quality springs, wire forms, assemblies, and flat metal parts with thousands of applications across the globe and beyond.

RCS can design and manufacture compression springs from 0.008" up to 1.375" diameter wire and bar stock. Round, square and rectangular cross sections are available for compression springs.

We are able to design and build extension springs from 0.015" to 0.630" diameter wire. Infinite hook variations are manufactured as well as extension assemblies with coned or threaded terminals.

RCS is capable of designing and producing torsion springs from 0.015" to 0.625" diameter wire and bar stock. Round, square and rectangular cross sections are available as well as tapered or multiple diameter springs.

Typically clock springs provide much greater rotational deflection than standard torsion springs. We design and manufacture clock springs from 0.005" up to 0.200" thick materials. These springs are also known as spiral torsion or hair springs.

For high load applications with a small installation space, RCS can design and build custom belleville or wave washers.

In the aircraft and automotive industries, these are used as vibration-damping elements because of their extremely detailed tuning ability.

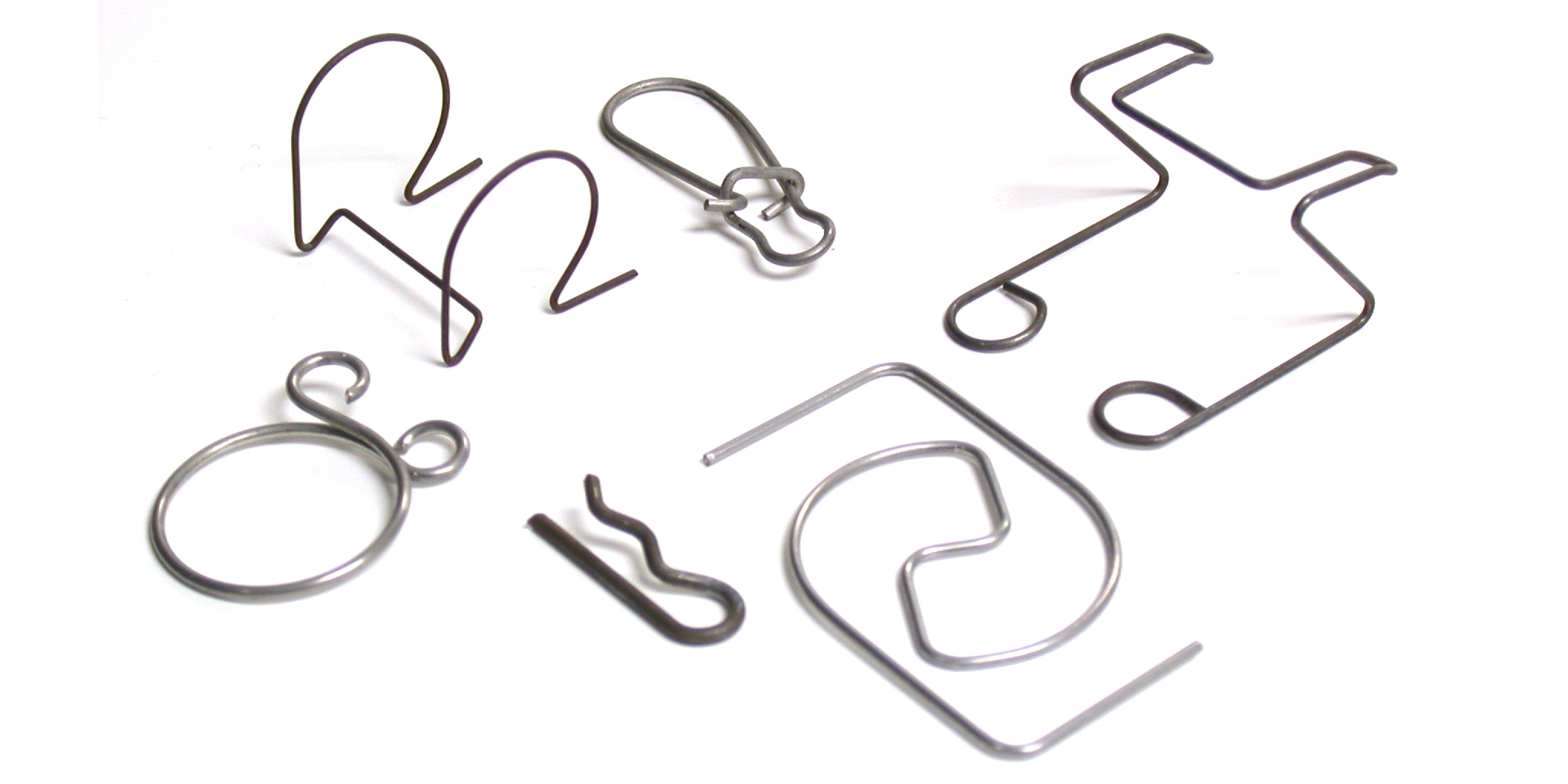

Renton Coil Spring can create wire forms from material 0.025" up to 0.250" diameter wire and bar stock.

Wire formed components can be designed, manufactured and installed into assemblies

or subassemblies such as spring loaded canisters,

reels and other devices.

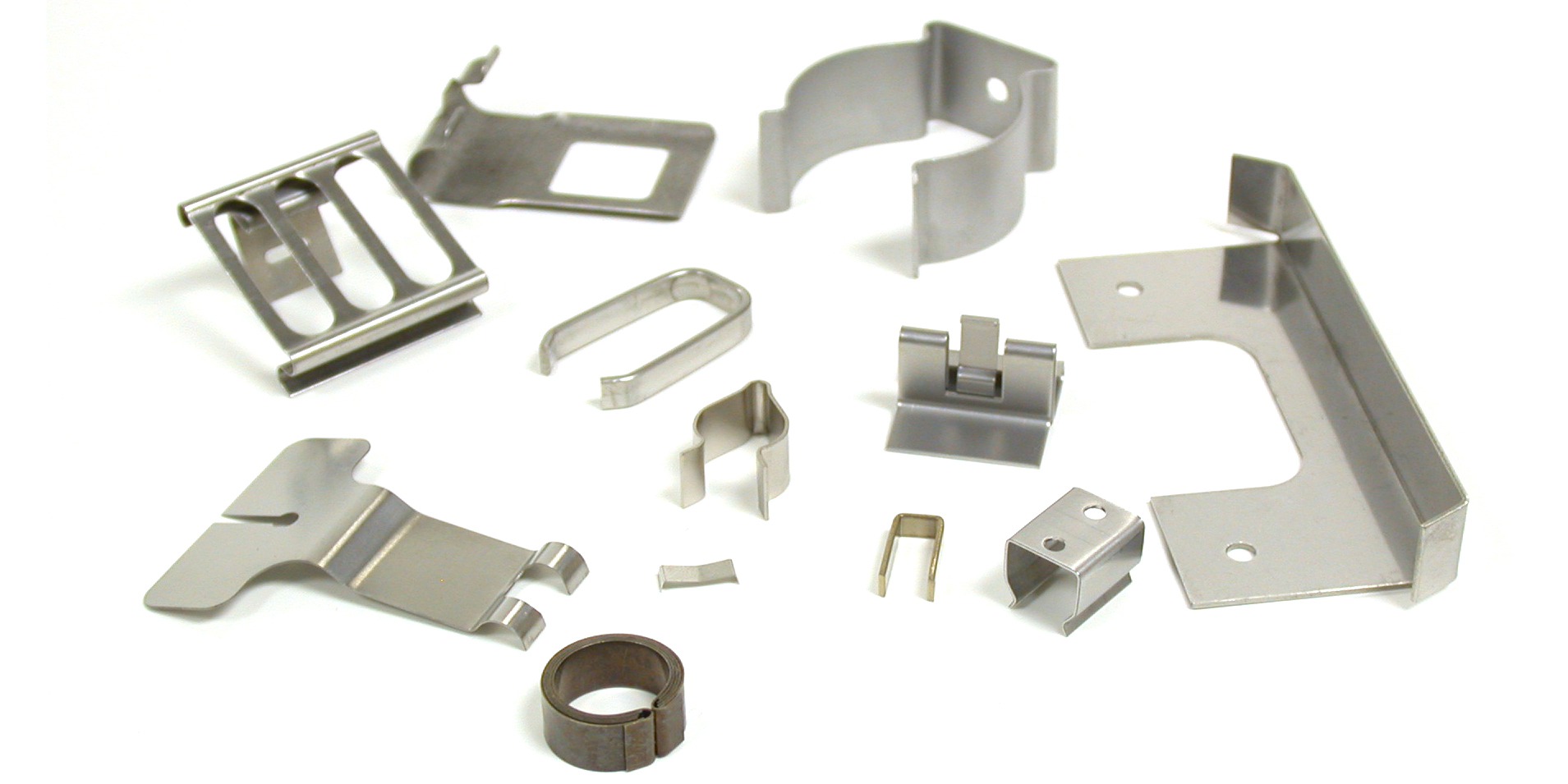

RCS progressive tooling designs allows production

of complex, close tolerance flat parts in an economical and timely manner.

With in-house stamping capacity of 50 tons,

material from 0.003" up to 0.125" thick and from

0.050" to several inches wide can be stamped and

formed to close tolerances.

Renton Coil Spring has the capability to coil springs from round, square, or rectangle cross section wire and bar. The stamping and forming department has the ability to work with flat, sheet, and strip material. Although RCS specializes in titanium springs, we can also manufacture springs from a large number of standard ferrous and non-ferrous materials.

Renton Coil Spring has designed, manufactured, and tested titanium springs for demanding aerospace, commercial and motorsport applications for over 30 years. Current and future efforts focus on bringing state of the art design and manufacturing expertise to new markets where performance counts.

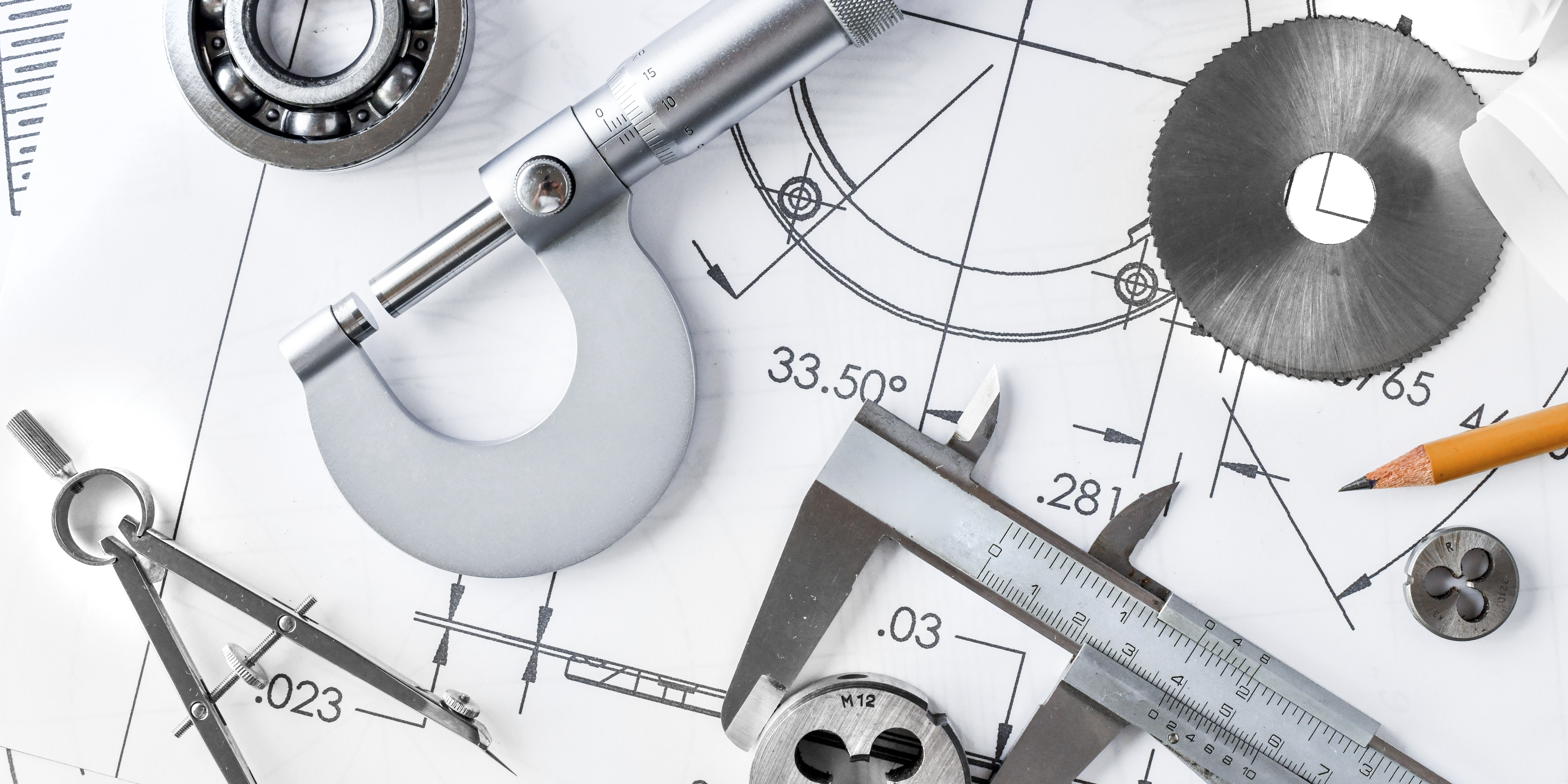

Renton Coil Spring has in-depth design capabilities utilizing proprietary spring design software, computer modeling in Solid Works & CATIA, and is one of the few spring companies registered to ISO 9001. This certifies that RCS has the ability to create drawings reflecting your specific design requirements. If you prefer to create your own drawings, we can evaluate your drawing prior to production.

Renton Coil Spring has a complete facility that utilizes state of the art tooling and equipment. Being a premiere supplier and technology leader, much of the spring manufacturing equipment and tooling have been designed and developed by RCS. The capable and experienced staff of machinists allows more flexibility and cuts down on the lead time and cost of new projects and are constantly improving existing processes.

Renton Coil Spring's aerospace certified ovens are capable of temperatures up to 1200°F. This gives RCS the capability of aging and stress relieving of AMS H 6875 (MIL H 6875), AMS 2801 (MIL H 81200), AMS 5699, BAC 5617, BAC 5619, DPS 5.00, DPS 6.33, and many others. Renton Coil Spring is also a NADCAP certified heat treating facility.

Renton Coil Spring works with several approved local finishing companies who perform a variety of material finishes.

Renton Coil Spring's quality system is certified to ISO 9001:2015, AS9100D, and also carries NADCAP certification and Boeing accreditation, along with ITAR registration. Traceability is maintained on all raw material and finished products with records kept for the amount of time specified by the customer. RCS exclusively uses material suppliers that self-certify (1 in 25 material lots is tested to verify conformance with chemistry and mechanicals).

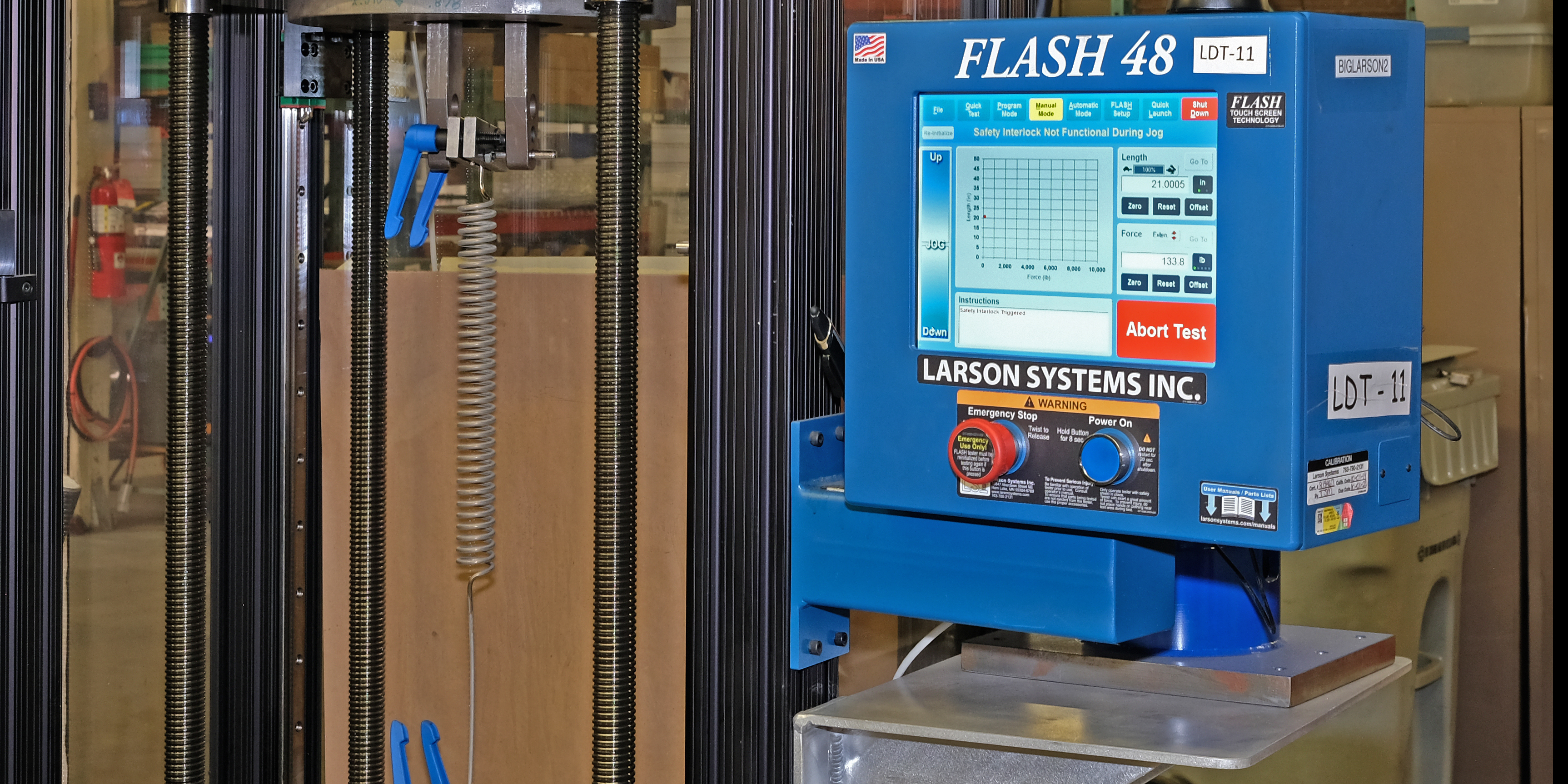

Renton Coil Spring's capability does not end with the manufacturing of springs. RCS is able to cycle test compression springs, extension springs, torsion springs, double torsion springs, clock springs, and assemblies. Extensive methods are used to recreate specific in-use conditions for springs and components. RCS has been a crucial partner for cutting edge aerospace, commercial, and motorsport companies in developing testing methods and procedures.